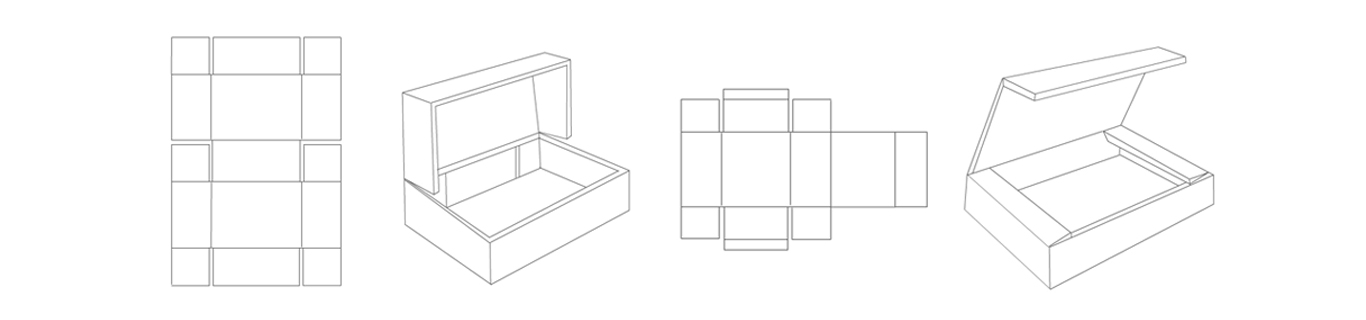

REGULAR SLOTTED CARTON (RSC)

The most popular corrugated container, manufactured in a variety of flutes, A, B, AB, E, BE, C. All flaps are of the same depth, and the

two outer flaps (normally the lengthwise flaps) are one-half of the container width, so that they meet at the centre of

the box when folded.

This is a highly efficient design. The only overlap is the flap for gluing or stitching of the manufacturer's joint, and the inner (or minor)

flaps.

Printed Carton can be used for most products, and is the most common box style.

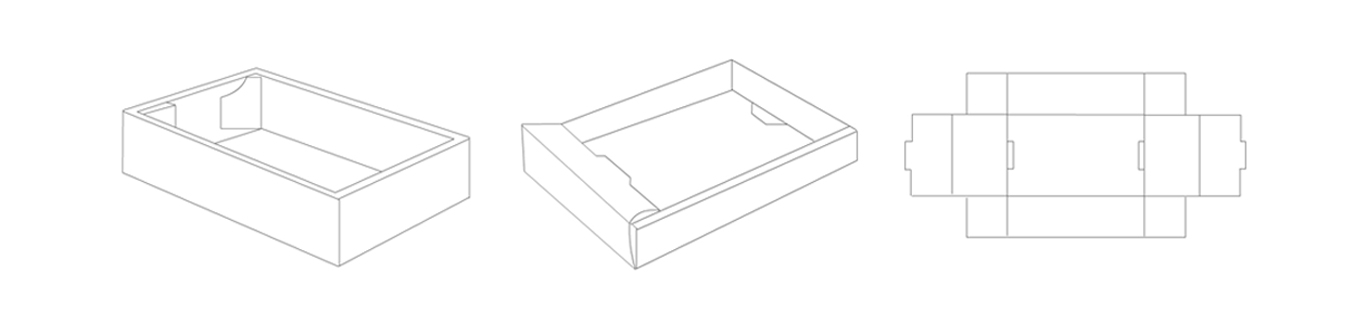

There are various styles of trays, from the simple double endwall self-locking (tuck-in) to the self-locking tray with cover. Trays normally made up of B flutes for easy folding. Perforation line along the folding edges may help in its folding during the feeding process on auto-packing line.

Trays generally apply to those products which require self-support and in rigid form container. After shrink wrapping with thin layer film that tightens the products in position, tray will act as a support. Trays are not shipping containers, but they are frequently used as inner container for parts, delicate products, letter, mail and so on, or as an element of the display stands.

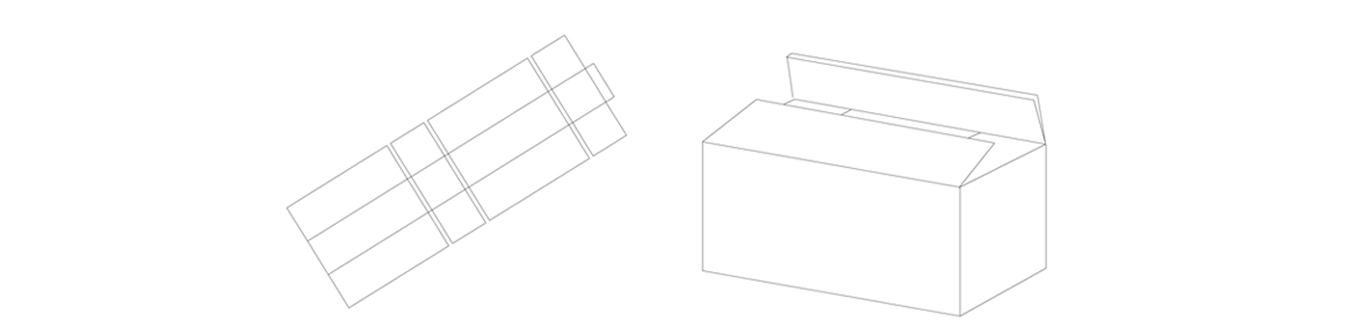

The joint flap is not as deep as the full side panel, and the end flaps do not overlap. In addition, the dimensions are less elongated. The finished box is essentially an RSC, turned on its side so that the bottom and top are unbroken.

The joint, however, is not formed until the final closure on the auto-packing line. A wrap-around carton is formed into a box by folding it tightly around a rigid product. This form of on line packing is compact and fits tight. The evenly folding of cartons are also more stable on stacking pallets. The positioning of the product, folding and sealing are performed automatically by equipments.

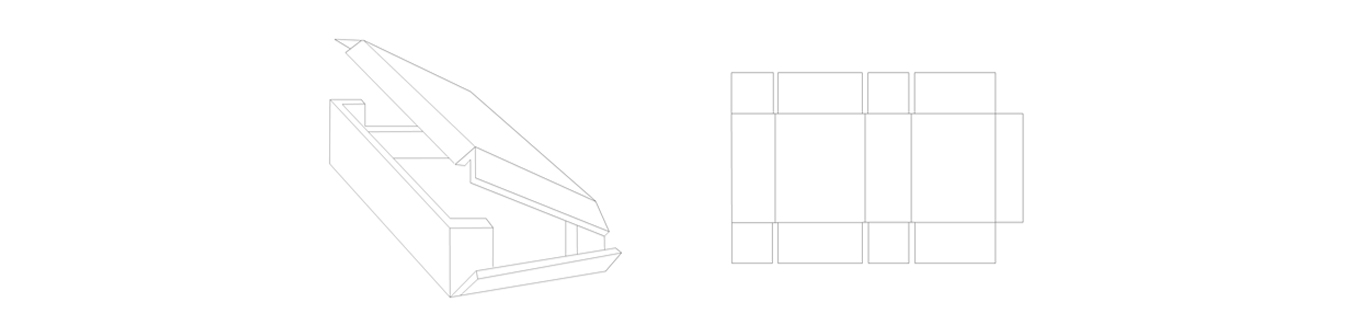

Besides the above cartons that are normally used in packaging finished goods, there are literally thousands of structural package designs for corrugated. With the state-of-the-art of die-cut mould design nowadays, any forms of cartons can be done to suit the packaging purposes and market point of sales.